| Research topics: For more information visit: http://www2.kaiyodai.ac.jp/~osakabe/ |

|

(1) |

Research relating to next generation regional energy supply (SMART) |

|

Related instructor(s): Masahiro OSAKABE and Sachiyo HORIKI |

|

Outline: |

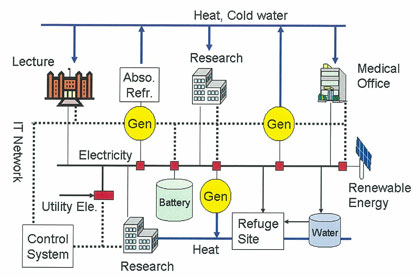

Demand for electricity during the daytime and at night differs several times over, and even the fluctuations in a country's economy will have a significant effect on electricity demand. These circumstances make it is unrealistic for large-scale concentrated electrical power supplies to continue operating at full power. Furthermore, in the Long-term Energy Demand Outlook of July 2001 the target figure for the introduction of new energies such as wind power and solar power generation in 2010 is stated as 1.35% of overall electrical power consumption (three times that of fiscal 1999). While this is an extremely important national measure for curbing the use of fossil fuels, their power generating power output is highly variable. For this reason good sense demand groups (good citizens) are demanding the equalization of loads on external power input via internal power generation, electrical and thermal storage, and coordination of demand while using natural energy. A new energy supply technology, SMART (SMall Advanced Regional-energy Technology), which aims for energy bidirectionality using IT, will make such hopes possible. This topic furthers research that brings regional energy supply, including reduced energy costs at the university, operational management of equipment (acquisition of maintenance skills), and accident prevention and restoration, into perspective. |

|

|

|

Figure 1. Conceptualization of a next-generation regional energy supply system |

|

|

(2) |

Research relating to micro steam injectors |

|

Related instructor(s): Masahiro OSAKABE and Sachiyo HORIKI |

|

Outline: |

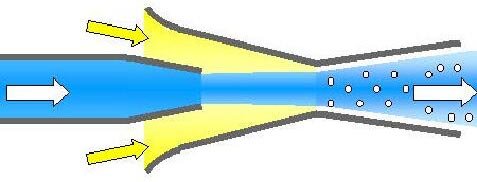

This research topic conducts experiments using an ultra-small micro steam injector (MSI) that has a water jet outlet with a diameter of 3.15 mm. In the diagram yellow represents steam and light blue the flow of water. MSI experiments using pure steam proved that a high degree of vacuum could be obtained. It is considered that in these situations the steam is accelerated up to the range of the speed of sound and then violently condenses on the surface of the water jet. Conversely, if a small quantity of air is mixed in with the steam and used in the MSI, the injector's performance is vastly reduced. Furthermore, an extremely fine water jet approximately the size of the lead in a pencil using pure steam will have 20 kW of steam condensing capacity, making MSIs a promising option as an ultra-small heat sink. |

|

|

|

Figure 2. MSI behavior when air mixed into injector |

|

|

(3) |

Research relating to header flow distribution |

|

Related instructor(s): Masahiro OSAKABE and Sachiyo HORIKI |

|

Outline: |

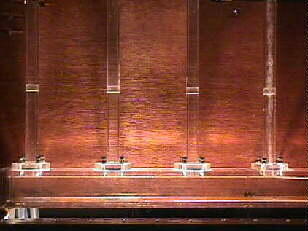

This research attempts to transform the distribution headers used in such devices as heat exchangers into a thinner form. In the methods of designing traditional header tubes the size of the header tube was enough large to ensure a uniform distribution with mitigating the pressure recovery behavior. The laboratory's research into small and thin header tubes has shown that, converse to tradition thinking, reducing the size of the header tube increases such factors as pressure loss within the header, and counterbalances the pressure recovery. These results indicate a transformation in the thinking linked to methods of designing header tubes. In addition, the research has clarified the distribution characteristics when air bubbles are mixed in, leading to a protruding-type header being devised that minimizes the impact of such bubbles. This special structure has attracted the attention of commercial manufacturers and other researchers, and it is hoped that the design will see vigorous practical application in the future. |

|

|

|

Figure 3. Visualization test using a transparent header |

|

|

(4) |

Research relating to vapor degreasing |

|

Related instructor(s): Masahiro OSAKABE and Sachiyo HORIKI |

|

Outline: |

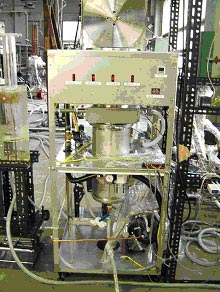

The research conducts experiments on the use of steam vapor to clean and remove cutting oil lubricants or other adhered substances from machinery parts. Specifically the research is focusing on a method of degreasing while subjecting the machinery parts to reduced-pressure boiling in a tubular container. At the present time a low-pressure low-temperature steam at below 60°C achieves a greater than 95% rate of grease and oil removal. Through these series of achievements Japanese manufacturers have developed commercial products:

[Patent number 3234204: Cleaning method and device for goods and other articles] and [Patent number 3190261: Degreasing and cleaning method and device for small mechanical parts]. |

|

|

|

Figure 4. Vapor degreasing device under trial production by a commercial manufacturer |

|

|

(5) |

Research relating to an exhaust gas latent heat recovery heat exchanger |

|

Related instructor(s): Masahiro OSAKABE and Sachiyo HORIKI |

|

Outline: |

This research topic conducts experiments into the recovery of water vapor latent heat in exhaust gases such as those derived from fuel cells. The achievements of these experiments are summarized in the latent heat recovery heat exchanger design code CHAC, presently used by 11 boilermaker firms in Japan. In addition, experiments using capillary tubes with greater performance have facilitated the design of an extremely compact heat exchanger far smaller than previous models. [Patent Application: 2000-19441; Patent Publication: 2001-208302: Condensing economiser for oxygen-combustion boiler]. |

|

|

|

Figure 5. Interior of latent heat recovery heat exchanger |