| Research topics: |

|

(1) |

Heat transfer and pressure drop in single-phase turbulent flow inside internally helically grooved tubes |

|

Related instructor(s):

Masao GOTO and Norihiro INOUE |

|

Outline: |

The heat transfer enhancement and the reduction of pressure drop of heat exchangers using the micro-cannel and optimization of inner grooves are required for the high performance and reduced size of air-conditioning equipment that aims for energy saving. In this study, heat transfer and pressure drop in some kinds of internally helically grooved tubes, which are seen as effective for increasing performance and reducing pressure drop, are measured through experiments. |

|

|

|

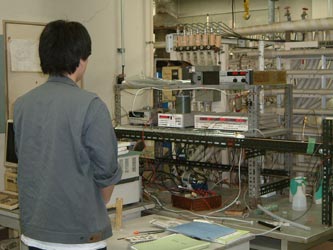

Figure 1.

Experimental apparatus for pressure drop and heat transfer of internally helically grooved tubes |

|

|

(2) |

Heat and mass transfer inside absorber in environment-conscious absorption refrigerating machine |

|

Related instructor(s):

Norihiro INOUE and Masao GOTO |

|

Outline: |

Ammonia is now being reconsidered as CFC and HCFC-free materials to help reduce the impact of environmental issues such as global warming. Ammonia is also one of the natural working fluids and has a higher latent heat of vaporization compared with HFCs. For the effective energy utilization and recycling of waste energy of low quality heat sources, there has also been a growing interest in absorption refrigerators using ammonia, which can cover the temperature range below the freezing point of water. Focusing on experiments that envisage an absorber for an ammonia-water system, this area of research aims to elucidate the basic phenomena behind various test conditions that influence heat and mass transfer in liquid film absorption. |

|

|

|

Figure 2.

Experimental apparatus for heat and mass transfer inside an absorber |

|

|

(3) |

Condensation heat transfer on water-repellent surface-coated tubes |

|

Related instructor(s):

Norihiro INOUE and Masao GOTO |

|

Outline: |

Experiments are conducted with a horizontal single-tube condenser, which allows condensing mode observations, using media such as distilled water, ethanol or high-boiling HFC. Students verify the basic heat transfer characteristics of normal surface copper and aluminum tube, and water-repellent surface-coated tubes. Students also investigate a variety of situations for condensation patterns, and a change in characteristics with the time of surface corrosion and the durability of water-repellent surface coats. |

|

|

|

Figure 3.

Experimental apparatus of condensation heat transfer on surface-coated tubes |

|

|

(4) |

Condensation and absorption heat transfer characteristics, hydrophilic effects and corrosion resistance of photocatalytic surface-coated tubes |

|

Related instructor(s):

Norihiro INOUE and Masao GOTO |

|

Outline: |

Students drop fluids such as distilled water, ethanol or high-boiling HFC onto a test plate to monitor contact angles in surface-coated plates. Students also evaluate corrosion resistance in each of the surface coats by using an electron microscope to observe the initial state of surfaces and the change in characteristics with time, and by observing initial mass and the change of weight with time using an electronic balance. At the same time students verify condensation and absorption heat transfer characteristics. |

|

|

(5) |

Effective utilization of heat energy and environment protection technologies for sea vessel engine systems |

|

Related instructor(s):

Norihiro INOUE and Masao GOTO |

|

Outline: |

The Kyoto Protocol went into effect on February 16th, 2005, and ratifying countries – including Japan – have been required to reduce greenhouse gas (GHG) emissions. Previous vessel engine systems required high efficiency in terms of energy consumption and used waste energy in all parts of the engine system, which is why there are so few heat resources in current vessels. But heat resource energies such as high temperature steam, low temperature waste energy from cooling engine systems, and so on are not used in the vessel. Students use system simulations under a variety of conditions to verify a reduction in environmental load, such as reductions in the amount of CO2 emissions, by estimating efficiency improvements in the component equipment in the system based on actual data obtained from sea vessel monitored data. |

|

|

(6) |

Next-generation power-recovery technologies for a compression refrigeration cycle |

|

Related instructor(s):

Masao GOTO and Norihiro INOUE |

|

Outline: |

The trend toward the use of natural refrigerants in the refrigeration and air-conditioning field has accelerated due to common perspectives on environmental protection. CO2 , a strong candidate as a next-generation refrigerant, at present brings about an unavoidable reduction in system performance if it is used in household air conditioners or other similar equipment. Students carry out experiments to clarify information and to develop such concepts as optimal forms in power recovery technologies that are designed to keep system performance at current or higher levels when using CO2 as a refrigerant. |

|

|

|

| Figure 4. Energy Conversion Laboratory (1) |

Figure 5. Energy Conversion Laboratory (2) |

|